Process

HOW TO PRODUCE ETHANOL FROM CASSAVA

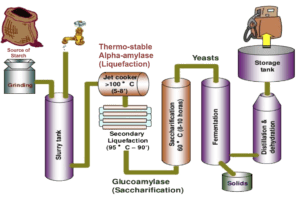

The Ethanol production process has 5 main steps: Grinding (prepare cassava to make suitable for downstream processing); Liquefaction; Saccharification; Fermentation and Distillation. Each of these steps are illustrated and further described below.

STEP 1. GRINDING

Cassava roots are cleaned, peeled, crushed and then refined into a pure starch milk that is then dewatered and dried into quality Cassava Starch.

STEP 2. LIQUEFACTION

In this step, the Cassava Starch is first cooked down to a gravy-like substance. Then, the liquefaction process begins with partial hydrolysis to lower its viscosity. This thinning process is helped along with enzymes called alpha-amylase, which break down longer starch chains into smaller ones.

STEP 3. SACCHARIFICATION

In this step, Glucosdiase enzyme is provided under controlled conditions. Usually the temperature is maintained between 55-65 Celsius and the pH between 4-4.5. The purpose of this step is to convert the starch and cellulose molecules contained into sugar molecules. After successive saccharification procedures, the mash will be cooled to room temperature, approximately 30-33 Celsius.

STEP 4. FERMENTATION

Once cooled, the yeast extract should be added to allow fermentation. Saccharomyces cerevisiae contained in yeast become activated. Due to this microbial activity, starch and sugar in the sample are broken down. Resulting products of this stage are Ethanol and Carbon dioxide, and solids are removed.

STEP 5. DISTILLATION

Since CO2 was already emitted during the Fermentation step as gas, only water is left with the Ethanol. Therefore, Distillation is done to evaporate the remaining amount of water, yielding anhydrous Ethanol (99.5 percent).

STEP 6. DISTRIBUTION AND BLENDING

Ethanol can be sold to oil companies and delivered to blending stations by trucks. At the blending

stations, three methods can be used: 1) in-tank re-circulation; 2) static mixer; and 3) in-line blending. The first two methods require tanks for handling the ethanol fuel, while in the “in-line blend” method, gasoline and ethanol are blended directly in-line before being transferred by truck and ship to the gasoline station for domestic consumption. At the blending stations, the tank blending process uses pumping machines to deliver gasoline and ethanol into one tank and to perform re circulation within this storage tank. Most of the petroleum distribution companies choose the “in-line blend” method. Most of the petroleum distribution companies choose the “in-line blend” method.

STEP 7. DISTRIBUTION OF ETHANOL BY-PRODUCTS

Besides ethanol, by-products include dried distillers drains sold for animal feed production, biogas used as a supplemental energy, and CO2 collected for sale for the beverage industry.